Recycling is the process of collecting waste materials, transforming them back into raw materials, and processing them into new products.

The amazing magic of turning trash into useful products again is what made recycling so popular since basically forever. Imagine this: the first documented use of recycling dates back to 1031 when Japan began reusing waste paper. Quite amazing, right?

“Recycling means creating less waste and using less raw materials for the creation of products hence why it’s so beneficial for the environment. ”

The recycling process can happen in three different ways but they all have three steps in common:

Collect and separate recyclable materials from waste.

Apply one of the three known procedures (we will explain them in a moment) to the residue and revert it into raw material.

Turn the raw material into a finished product again.

Recyclable materials can be turned into new products in three different ways:

Mechanical Recycling

One of the most globally used methods of giving residues new usages is mechanic recycling. This method is used to recycle plastics, paper and glass. The residues of all these materials are mechanically transformed into new materials without changing their chemical structures.

Mechanical recycling is the process of making plastic wastes useful by processes like grinding, washing, separating, drying, re-granulating, and compounding.

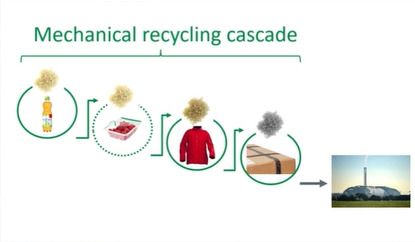

The majority of plastic recycling worldwide happens through mechanical recycling. Ideally this process allows to recycle a material back into the same application ( referred as “closed loop”), just like it happens with glass. Nonetheless, there are other materials, like plastic, that after being recycled more than once, lose quality and are therefore degraded. This translate in lesser and lesser quality of the final products. We refer to this with the term “cascade recycling”.

In the example above a PET bottle is recycled into a plastic film. The plastic film is downcycled and can be used as a clothing material (a non-food application) which is then downcycled into packaging. As you can see, this cascade is usually down in the direction of quality. This means that while mechanical recycling can recover a lot of plastic and give it a second or third life, it will eventually put an end life to plastic when its quality is not good enough for another step.

Recyled PET flakes ready to be used.

2. Chemical Recycling

Chemical Recycling is a recently new technology that promises to bring back material from any of the cascade steps all the way back to the raw, high-quality material we had in the first place. Chemical recycling is actually the umbrella term for several different processes. These processes differ in how they break down Polymers, the big molecules that make up the plastic materials.

2.1. PYROLISIS

The first Chemical Recycling process is pyrolysis. Pyrolysis is a process in which polymers are heated in the absence of oxygen. During this process, polymers break down in smaller parts and behave like a type of oil. Under the right conditions, the synthetic oil fraction obtained is very similar to petrochemical naphtha and can be used as feedstock in the petrochemical industry for the manufacture of chemicals, synthetic rubber, and a variety of plastics.

2.2. GASIFICATION

The second possible process is gasification. It involves heating polymers up, but in this case, in presence of oxygen and water. The end product here is a mixture of gases referred to as syngas that can be used as a chemical feedstock in the chemical industry.

2.3. DEPOLYMERIZATION

Finally, we have a process called depolymerization (possible only for certain types of plastic). This process cuts down the polymers into monomers so the output is not oil or gas fraction but a starting material directly for the production of new plastic.

With CR you go back to feedstock material so then you need another polymerization to create plastic.

3. ENERGY RECYCLING

The third option is energy recycling. This approach only works with plastic waste and it consists of converting plastic into both thermal and electric energy by leveraging, through incineration, the heat power released by these materials in the form of fuel. Energy recycling is very popular in some countries since it allows to optimize the space available in heavily populated cities with little room for landfills. This solution is widely used in Europe and Japan, but requires heavy investments.

In the ’70s and ’80s, energy recycling used to be negatively seen because of the emissions it produced. Today, clearer rules have been set for incineration equipment to work properly and ensure emissions are more environment-friendly. For example, newly created waste incineration plants for energy recycling use catalyzers to withhold emissions.

A waste-to-energy plant in Belgium.

CONCLUSION

Be it mechanical, chemical or energy, recycling is the most environmentally-friendly option we have to treat our waste. And it comes with incredible savings: indeed, recycling one ton of plastic can save: 5,774 kWh of energy, 16.3 barrels of oil and 30 cubic yards of landfill space! Compared to the amount of energy used in the creation of virgin materials, more than 80% of energy in the process is saved! Quite outstanding, right?

Then let’s keep recycling and, at the same time, reduce our consumption and use reusables for a cleaner world!