Did you know that today, 95% of plastic packaging material, valued at USD 80–120 billion annually, is lost to the economy. A staggering 32% of plastic packaging escapes collection systems, clogging urban waterways and polluting the ocean. The negative impact is estimated to cost society 40 billion USD annually. This exceeds the plastic packaging industry’s total profit pool.

With all these growing environmental pressures, why are recycling rates for plastic still between 5-9%? Over a billion metric tons of plastic has been created in the last 50 years. Shouldn’t it be easier to recycle the plastic that already exists rather than extracting new plastic from the beneath the earth’s crust?

Source: The Next Wave

Here are the top six factors inhibiting the circular economy in developing regions. We’ve compiled these factors from listening to the members of the informal recycling economy. After all, in developing countries 80-90 percent of the recycling activities are informal.

Here are the top six factors inhibiting recycling rates in developing regions.

1) Lack of household collection and segregation.

Globally, some 3.5 billion people lack access to formal waste management services. The World Bank estimates that global solid waste generation is on pace to increase 70 percent by 2025. Municipal budget can’t keep up with the growth in consumption because unsegregated household waste is expensive to collect and process.

In most developing countries 80-90 percent of the recycling activities are informal. These urban mining entrepreneurs save municipalities millions by preventing the waste from being trucked to landfills. A human centric approach is needed for supporting the informal recycling economy and creating inclusive market systems.

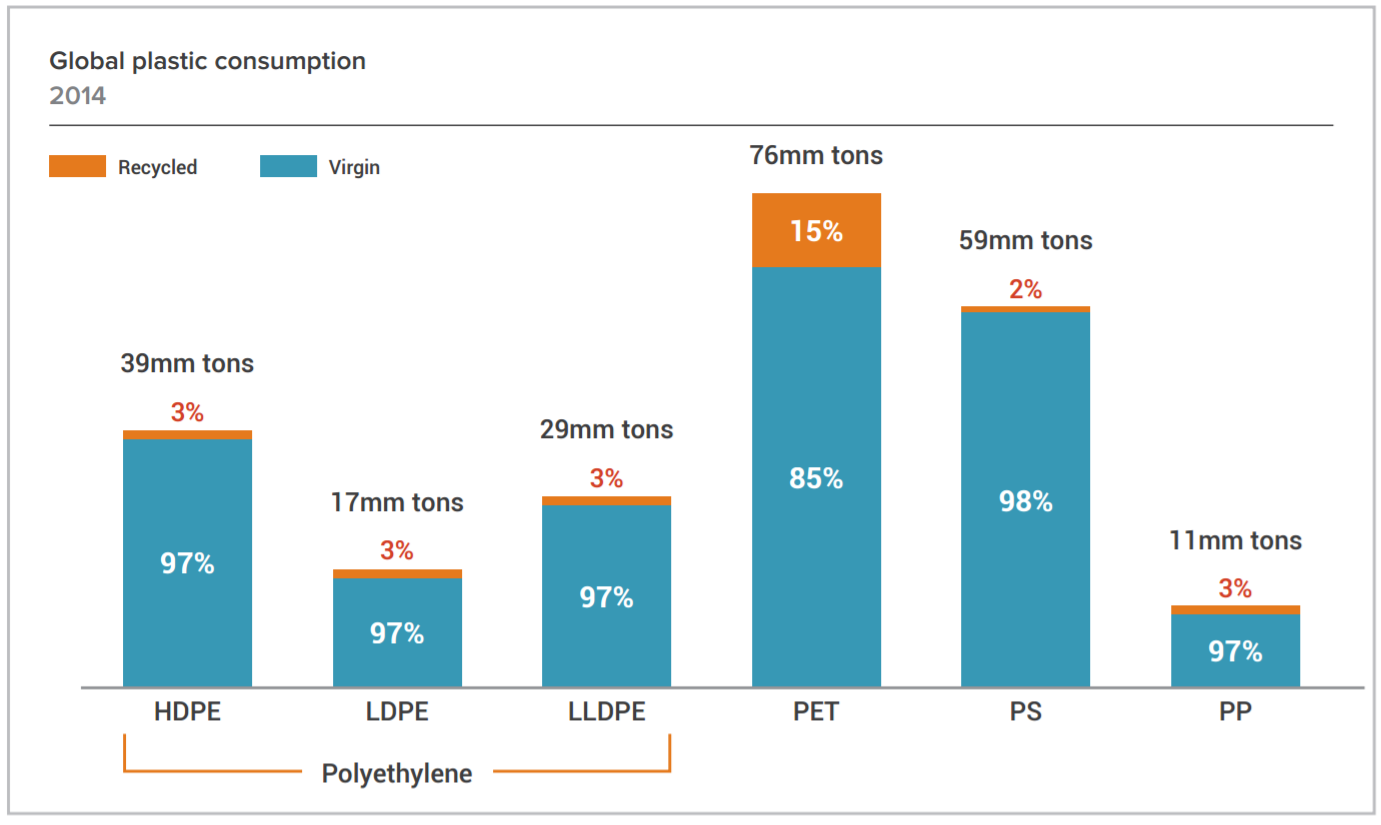

2) Competition with virgin plastic

The virgin plastics industry consumes 6% of global oil consumption. That is more oil than the entire aviation industry. The economies of scale make it much easier for manufactures to source virgin material vs recycle.

From our research, we found that only 5% of the formal manufacturing facilities in India are sourcing recycled plastic. Often the raw materials managers’ haven’t received any training on how to source recycled plastics effectively. Our ethical sourcing platform is making it easier to source consistent supplies of high quality recycled plastic, but it ultimately take leadership from the industry to choose recycled rather than virgin materials.

The IMF estimates that the fossil fuel industry receives a 10 million USD subsidy every minute. It is imperative that policy makers also create incentives for the industry to source recycled plastic and create value from the plastic waste stream.

3) Volatility in the commodity value

The value of scrap plastic is constantly fluctuating. Those at the base of the recycling value chain suffer the most from fluctuations in price. When the commodity value of plastic falls they often have no savings to rely on as an insurance plan.

In 2015 when oil prices feel, the demand for recycled plastic also plummeted because it was cheaper to source virgin rather than recycled. This resulted in a 60% drop in the price that the wastepickers received for the plastic they collect. Wastepickers are often the most marginalized members of society, yet they're also the driving force behind the circular economy. When these informal waste workers stop feeding plastic into the supply chain, the entire recycling industry suffers.

At Plastics for Change, our strategy is to create resilient livelihoods for the wastepickers by hedging the price in advance with our corporate partners. This stabilizes the packaging costs for brands while also de-risking the supply chain for the aggregators/wholesalers who can accumulate the plastic in bulk without the risk of the price falling.

4) Access to capital

Many multi-lateral development funds, such as The World Bank have billions of dollars budgeted for investment in waste management. Yet, these institutions are incredibly ineffective at allocation capital to small scale projects. Multi-laterals generally only consider projects of five million dollars or more.

Plastics for Change is working in partnership with The Small Scale Infrastructure Development Fund ( S3IDF ) to bridge this gap between development finance institutions and small scale infrastructure investments.

Over 90 percent of the businesses participating in the plastics recycling industry in developing regions are small and medium size enterprises. The majority of these stakeholders don’t have bank accounts and cannot access loans. Even if these businesses can access loans, the interest rates in developing regions are typically 15-20%.

For example, one of the stakeholders participating in our ethical sourcing platform is a scrap shop owner named Chandprasha. He needs to close his shop for one week each month because while he waits until the end buyer in the supply chain settles, he doesn't have access to turnover capital to purchase more plastic during this lag.

Plastics for Change is addressing this problem by providing access to working capital finance through the ethical sourcing platform to ensure that all stakeholders receive prompt payments

"Interest rates on loans are 20%"

Photo: Hasiru Dala

5) Lack of advanced processing technology

There's at least 267 different types of plastic polymers. When these different polymer types are mixed together, it affects the material properties and can lead to defects in the manufacturing process. Advanced processing facilities are needed to create a high quality source stock of recycled plastic to offset the use of virgin materials.

The lack of advance recycling infrastructure in India is resulting in a colossal economic loss to the economy and a plethora of environmental and social consequences. The majority of the plastic is currently being down cycled into low quality plastic product. This is because very rudimentary technology is being used to melt and reprocess the scrap material.

In the US, The Closed loop fund was established to finance projects which scale recycling infrastructure and sustainable manufacturing technology. Brand owners contribute to this industry fund which allocates low interest loans for recycling infrastructure.

6) Education

Education is perhaps the most important factor in this list. Engagement and awareness is needed throughout the entire value chain to address these complicated problems.

Everyone has a role to play, from the consumer who purchases from responsible brands, to the designer who creates products that can be easily recycled, but most importantly brands and manufacturers need to create markets for the plastic waste stream by choosing to source recycled materials.

If you found this article interesting, please share this message. Solving these important issues is paramount for reducing ocean plastic and transitioning towards a circular economy.